Description

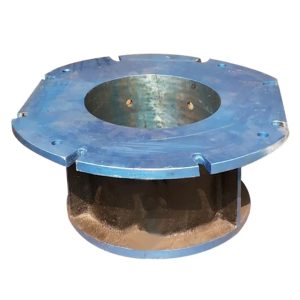

The Air Tube Swirler (also known as CB Swirler) is a precision-engineered component designed to improve combustion performance in industrial and ceramic kilns. By introducing a controlled swirl to the incoming combustion air, this swirler promotes better mixing of air and fuel, resulting in more efficient burning, reduced hotspots, and improved heat distribution throughout the kiln chamber.

Key Features

-

Enhanced Air-Fuel Mixing: Creates a swirling airflow that promotes complete combustion and reduces unburned fuel.

-

Improved Temperature Uniformity: Helps maintain consistent temperatures throughout the kiln for superior firing results.

-

Durable, Heat-Resistant Construction: Built to withstand high kiln temperatures and harsh operating conditions.

-

Easy Installation: Designed to integrate smoothly with existing kiln air systems.

-

Energy Efficient: Supports fuel savings by optimizing combustion efficiency.

Benefits

-

Boosts overall kiln performance and firing quality

-

Reduces fuel consumption and operational costs

-

Minimizes emissions and improves environmental compliance

-

Enhances longevity of kiln components with stabilized combustion

Reviews

There are no reviews yet.